Scalewatcher® Heavy Industrial series for pipes up to 80 inch

Features, functional drawing, inside view, dimensional drawing

Where can the product be used?

- Municipal water supply

- Food and beverage industry

- Metal factories

- Paper factories: Kraft, de-inking

- Petrol-chemical industry

- Power plants: coal, hydro, nuclear

- Chemical factories

- Pharmaceutical industry

- Gas refinery

- Mining

Additional Applications

- Semi-conductor Industry

- City heating

- Dairy industry

- Waste water plants

- Irrigation

- Large buildings

- Desalination plants

- Crude oil pipe lines

- Cement factories

- Zebra mussel prevention

The product reduces incrustation, corrosion, algae and bacteria as evidenced by numerous field reports. Zebra mussels will not settle when the water is treated.The Scalewatcher was developed back in 1988. Continuous improvements make this non invasive device probably the best one can buy.

Features

Protection against harsh environments.

The unit comprises non-corrosive components such as a stainless steel enclosure, serial number plate, and cable glands. The ingress protection is IP55 (weatherproof), optional is IP56 (waterproof). Only the IP55 model has a window for observing the unit’s status.

Easy serviceability.

The electronics consist of modules, which can easily be replaced in the unlikely event this is necessary. Only a screwdriver is needed. Furthermore, each module has integrated LEDs indicating the status to find the defective module.

Easy Monitoring of Output Strength

The inner door has a 7-segment display (meterboard), visible through a window, showing a value proportionately with the output current.

Performance of the Power Module

External parameters such as pipe material, diameter, and electrical conductivity of the fluid vary with each installation and influence the induction. An extra display, indicative of the deviation of the optimal induction achievable, must be set to a minimum by the one installing the unit.

Auto Reset

When for any reason the output current drops to zero, the unit will reset itself after ten seconds.

Electronic Fuse

The incorporated electronic fuse will trip, preventing the mechanical fuse from blowing, in case the output current is too high.

Easy Remote Monitoring of the Scalewatcher

Isolated relay contacts indicating the status of the unit can be hard-wired to an optional alarm unit or process table. Through the same socket, a voltage proportional to the output current can be monitored and transmitted and made visible on a dedicated website and/or mobile phone application (optional).

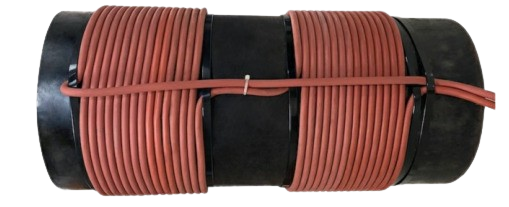

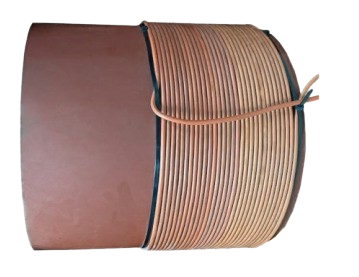

High-Temperature Coil Cable

The manufacturer only supplies silicone cable capable of withstanding 200 ºC. Optional is a heavy-duty low-temperature (QWPK) cable for harsh environments and a super high-temperature cable of 450 ºC.

Protection Against Emission and Susceptibility of Electro Magnetic Fields

Two EMI filters are incorporated to reduce emission of disturbing signals on the power grid of the factory, created by the Scalewatcher and to increase immunity against high electromagnetic energy picked up by the coil in the factory.

Test Device Included

Each unit will be supplied with a handheld test device. The test device is able to find the best location for the coil, free of disturbing signals. It also shows whether the correct signal is being generated.

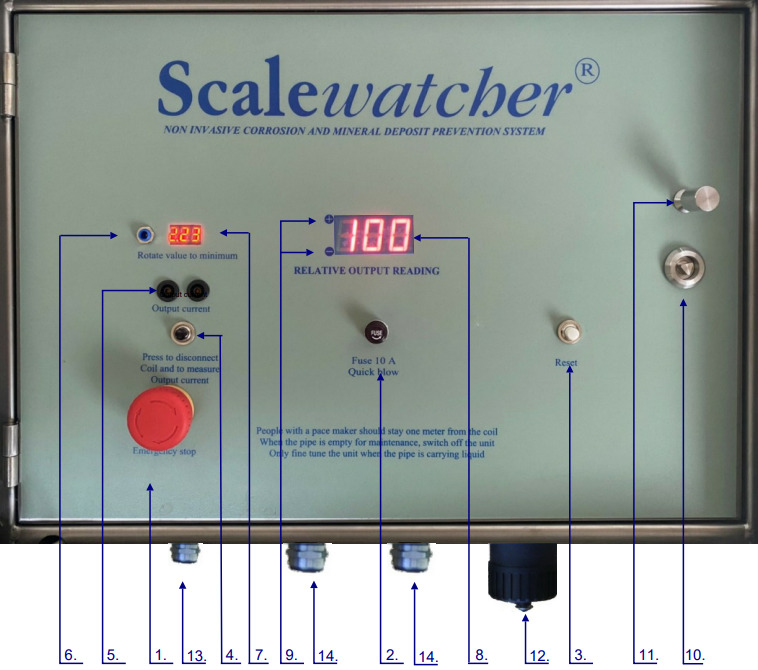

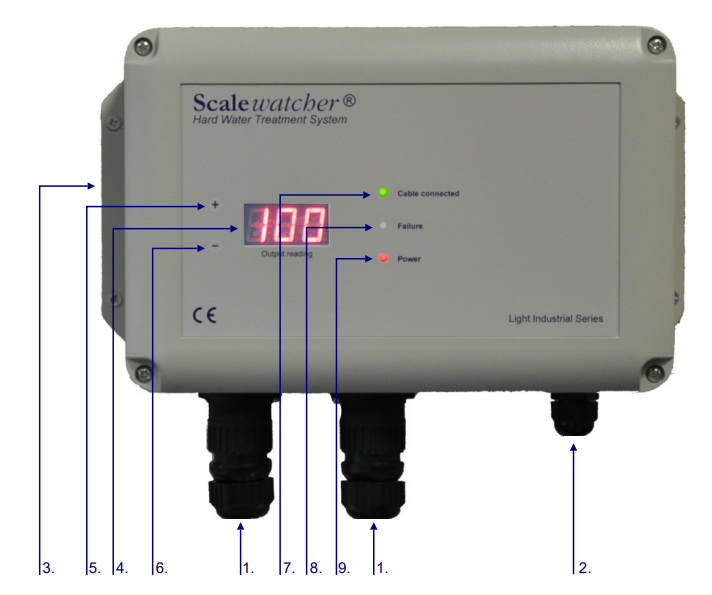

Details of front panel of the innerdoor

Two Signal Application Methods for Liquid in Pipe

Depending On The Model

SEF8, LEF12, LEF16,LEF20 for pipes with a nominal diameter of 8” (200 mm) to 20” (500 mm) Make two coils of 15 windings each in series, spaced 4” (100 mm).

HIME24, HIME32, HIME40, HIME60, HIME80 for pipes with a nominal diameter of 24” (600 mm) to 80” (2000 mm) Make one coil and adjust the windings such that the desired output current is reached.

Electrical and technical specifications

Technical Specifications

| Specification | Details |

|---|---|

| Supply Voltage | 115 V-240 V 50/60 Hz |

| Power | <155 Watt |

| Overload Protection | Internal mains fuse 3A, external fuse 10 A, quick blow. |

| Fuse Size | 0.8 x 0.2” |

| Standard Silicone Cable | Three cores |

| Maximum Coil Temperature (Continuous) | 356 °F/180 °C |

| Maximum Coil Temperature (Intermittent) | 428 °F/220 °C |

| Optional Heavy Duty Cable | -22 °F to 176 °F/-30 °C to 80 °C |

| Wired Remote Alarm | Isolated alternating switch, contacts rated 24V 1 A |

| Wireless Remote Alarm | Monitoring output current through IoT (Optional) |

| Indicators | 7-segment display, with self-test software. |

| Enclosure | Stainless steel |

| Protection Rate | NEMA4/IP55, optional IP56 |

| Weight (SE/LE models) | 24 lbs/11 kg |

| Weight (Up to HIME80) | 33 lbs/15 kg |

| Maximum Ambient Temperature | 140 °F/60 °C |

| Minimum Ambient Temperature | -22 °F/-30 °C |

| Humidity | 20-90% |

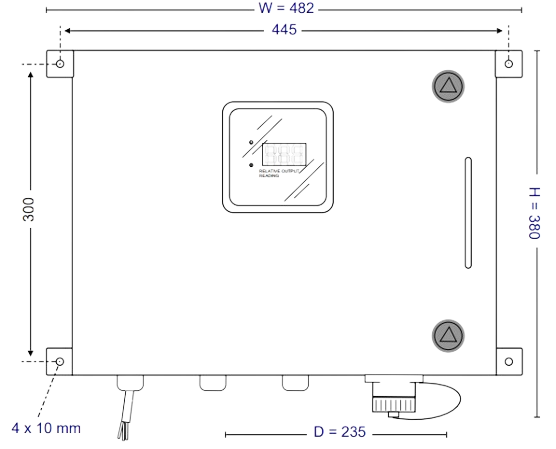

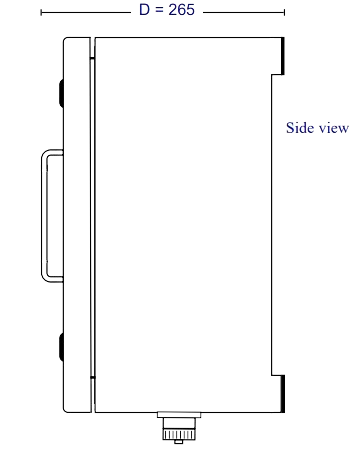

Dimensional drawing SEF and LEF models up to 20 inch

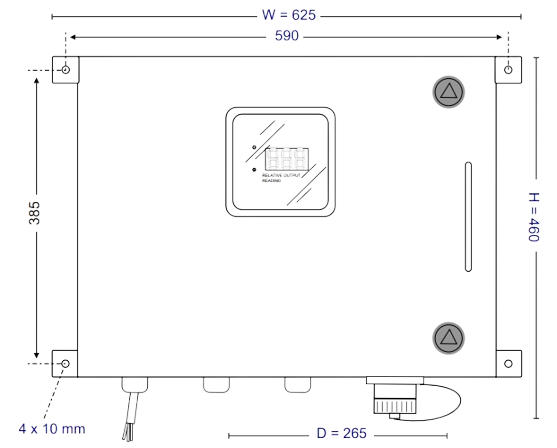

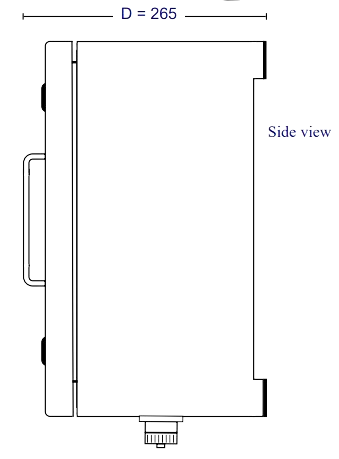

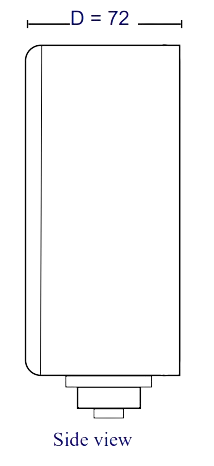

Dimensional drawing HIME models up to 80 inch

Test Drive

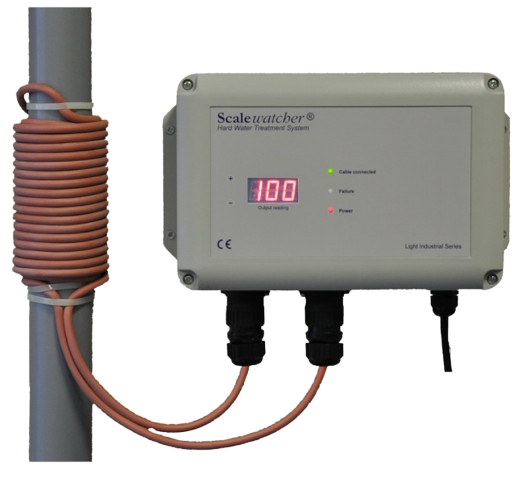

Scalewatcher® Light Industrial series

Features, functional drawing, dimensional drawing

Where can the product be used?

The Light Industrial unit is capable to treat Low TDS level waters, such as fresh and well water. This unit works excellent as POU (point of use) at industrial applications such a protection for Heat Exchangers, Water boilers, Steam boilers, Chillers, Small cooling towers, large Reverse Osmosis systems etc.

The unit shows also very good results in buildings such as;

- Semi-conductor Industry

- City heating

- Dairy industry

- Waste water plants

- Irrigation

- Large buildings

- Desalination plants

- Crude oil pipe lines

- Cement factories

- Zebra mussel prevention

In addition:

Lifestock

- Poultry farms

- Dairy industry

- Slaughter houses

- Fish farms

Agriculture

- Green houses

- Golf courses

- Irrigation

Light Industry

- Food and beverage

- Foundries

- Plastic industries

- Paper printing

Features

Protection against harsh environments.

The custom-made designed enclosure of the unit is made of aluminium with a protective powder coating. The signal cable sockets and cable glands are watertight. The ingress protection is IP66 (weatherproof), optional is IP67 (waterproof).

Display reading.

This meter gives the relative output strength, indicating the correct output is being generated.

Auto Reset.

When for any reason the output current drops to zero, the unit will reset itself after ten seconds.

Three LED indicators.

- The green LED shows only when the signal cable is connected, indicating that electrical current is being generated.

- The middle red failure LED will light up when the signal cable is disconnected or in the unlikely event, when something is wrong with the device.

- The bottom red LED will light up once the unit is powered up, which may take approximately 7 seconds.

Optional: Easy remote Monitoring of the Scalewatcher.

If the end user desires, the Light Industrial unit can be integrated with a relay with isolated contacts. These contacts can be hard wired to a process table. The relay is energized when the unit is in good working order.

High-temperature coil cable.

The manufacturer only supplies silicone cable capable of withstanding 200 ºC. Optional is a heavy-duty low-temperature (QWPK) cable for harsh environments and a super high-temperature cable of 450 ºC.

Return on Investment.

Generally, the Scalewatcher system's "return on investment time" is less than one year. Or even sooner for industrial applications due to the enormous savings in reducing energy, chemicals, and maintenance costs.

Details of the front panel

Electrical specifications

Technical Specifications

| Specification | Details |

|---|---|

| Supply Voltage | 110-230 V 50/60 Hz |

| Power | < 20 W |

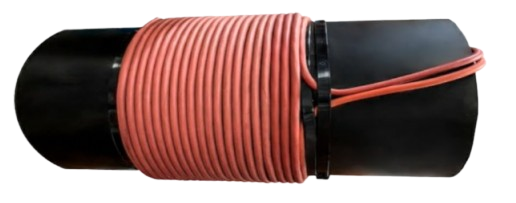

| Coil Configuration | Capable of driving 2 coils in series or double stacked |

| Coil Cable | Three core: 0.75 mm² |

| Outer Diameter | 7 mm |

| Maximum Coil Temperature | 230 °F / 110 °C (optional 392 °F / 200 °C) |

| Maximum Ambient Temperature | 122 °F / 50 °C |

| Enclosure Material | Aluminum |

| Protection Rate | NEMA5/IP66 |

| Weight of the Unit | 6.6 lbs / 3 kg |

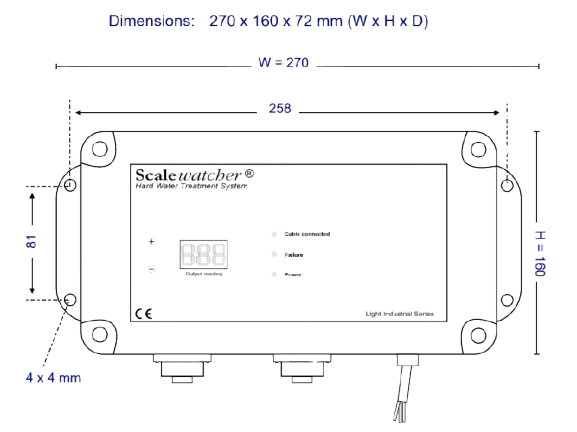

| Dimension Unit | 10.2" x 7.2" x 2.85" / 270 x 183 x 72.5 mm |

The coil design depends on the type of pipe material.

For Schedule 20 iron pipes up to 8” (20 cm): Double stacked coil of 20 windings each. For Schedule 40 iron pipes always use the heavy industrial units for best results.

For plastic or stainless steel pipes up to 20” (50 cm): Two coils of 20 windings each, in series spaced 4” (10 cm).

Dimensions of the IE unit

Industry Solutions

Water Treatment Services for Manufacturing, Healthcare & More.

Water Treatment Services for Manufacturing Businesses

Water Watcher can control the electric potential of positive particles around the surface of the water by modulating electromagnetism with a certain frequency from the outside of the pipe.

HVAC

Commercial Water Treatment Services for HVAC Boilers & Cooling Towers.

Heating, cooling and ventilation (HVAC) systems are critical in commercial and industrial operations. Organizations across different industries rely on their HVAC systems to deliver consistent performance to meet their facility’s unique needs. HVAC systems that utilize water must be treated with the utmost care to prevent corrosion, scale, and microbiological growth.

We provide services that can extend your HVAC system’s life and performance while saving you money.

Food & Beverage Processing & Cold Storage

We offer comprehensive cold water treatment solutions aimed at improving production efficiency through efficient cooling systems and water treatment methods. Using electromagnetic wave technology, we prevent biological contamination, scale, and corrosion, while saving money and reducing water and energy consumption.

Plastic

Reducing failure in manufacturing processes and increasing efficiency to maximize production results. Our solutions ensure efficient cooling towers and closed-loop systems for the plastics industry.

Healthcare

Patient care is the number one priority for healthcare facilities. We provide water treatment services to ensure safety and prevent potential contamination from cooling towers and boilers.

Automotive

We provide cost-effective water treatment services to support the global automotive industry in maintaining efficient and environmentally friendly manufacturing processes.

Data Centers

We provide tailored water treatment solutions for data centers, ensuring efficient cooling systems and protecting essential equipment from scaling, corrosion, and overheating.

Service Offerings

We provide efficient water treatment solutions to treat scale and rust without chemicals on your water equipment.

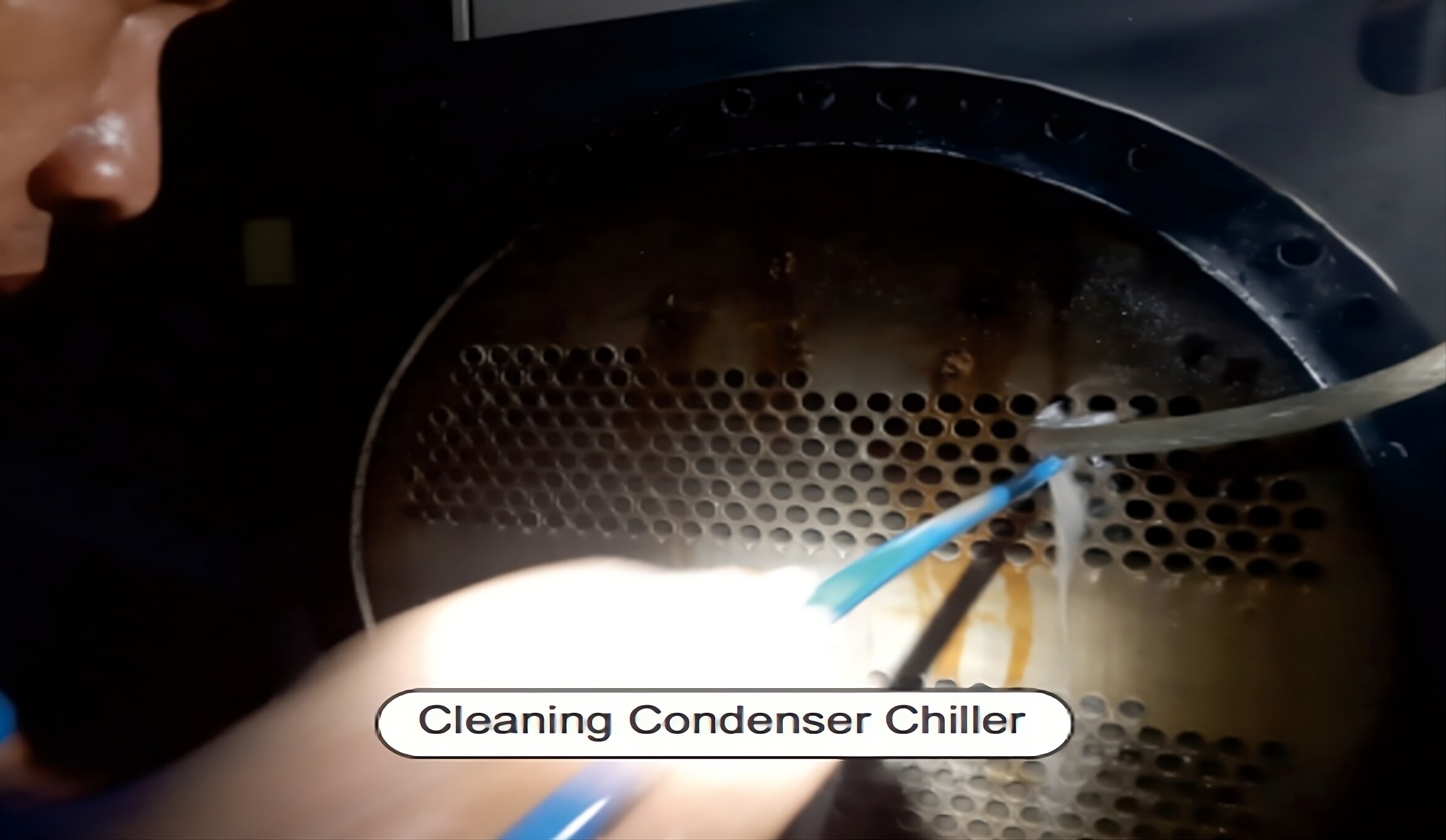

- Cleaning Fillers

- Cleaning Upper & Lower Basins

- Water Quality Checks

- Cleaning strainers

- Cleaning condenser tubes

- Mechanical scaling

- Maintaining condenser approach temperature within standards.

- Removes and prevents scale without chemicals

- Effective and efficient in dealing with scale and rust

- Saving electricity & Save water

- Longer equipment life

- The device does not need maintenance

- Environmentally friendly